Analyzing the Physical Mechanical Characteristics & Properties of Guadua vs Moso Bamboo

Guadua Bamboo by The Best Bamboo

In 2010, Larenstein University in The Netherlands conducted one of the most promising compelling study comparing the physical and mechanical properties of bamboo poles. The research report utilized Guadua Bamboo and Moso Bamboo Culms, recognized as prominent relatively large bamboo species in the world for industrial processing. On a personal note, I think bamboo as a construction material is one of the most ecofriendly and sustainable trees in the world (technically is a grass) and in the link bellow you will be able to find the full scientific report by Valentijn de Vos. While this is summary from a blog post by Stéphane Schröder that provides essential insights into the fundamental aspects required to comprehend the mechanical characteristics and properties of Guadua versus Moso bamboo, for a more in-depth understanding, it is recommended to refer to the complete article by Valentijn de Vos.

Approximately 50 popular bamboo species worldwide possess favorable properties for building materials, such as flooring, paneling, and laminated lumber. The focus on 'giant timber bamboo,' known for its considerable size and rapid growth, is particularly relevant due to its potential applications.

Phyllostachys edulis (Moso), the widely utilized bamboo species in global industrial manufacturing, is predominantly sourced from China, the largest producer. Conversely, Guadua angustifolia (Guadua), considered a sustainable construction material in Colombia, although less prevalent in industrial Western products, is crucial in South America. As industrial activities involving Guadua gain momentum, understanding its properties vs the mechanical properties of Moso becomes imperative.

The study subjected Guadua Angustifolia Kunth and Moso to mechanical property tests according to the KOMO-certified standard, widely adopted for outdoor bamboo materials in construction applications. The examination focused on single, non-laminated bamboo strips to capture bamboo's natural condition data. To establish a reference point, physical properties results were compared with two common wood species, Norway spruce and dark red Meranti, prevalent in the Dutch market for exterior applications.

Macroscopic Features of Bamboo (Moso vs Guadua)

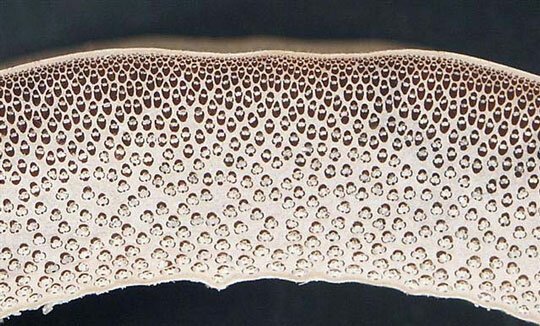

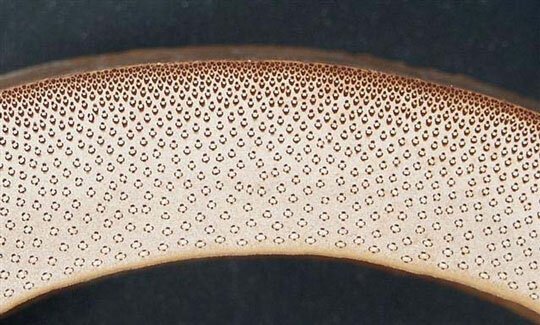

Moso exhibits a finer grain compared to Guadua due to smaller vascular bundles, resulting in a smoother surface after planing. Guadua, on the other hand, possesses a coarser grain attributed to larger vascular bundles, leading to a rougher surface. (We noticed this rougher finish on several of our laminated Guadua material properties that are composed by Bamboo Strips)

Microscopic Features of Bamboo (Moso vsGuadua)

The bamboo culm's ground tissue comprises parenchyma cells, vascular bundles, and fibers, more or less 52% of parenchyma, 40% of fibers, and about 8% of vascular conducting tissue. Both bamboo species exhibit variations in vascular bundle structure, impacting their strength. Guadua's bundles, with larger diameters and distinct organization, contribute to its stiffness.

Starch Content of Bamboo

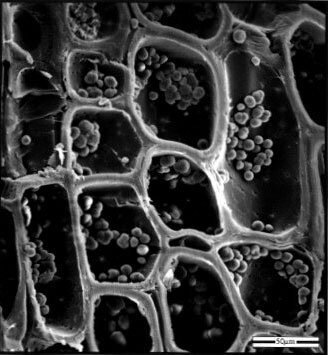

Parenchyma cells (ground tissue) filled with starch g in Phyllostachys viridiglaucescens

All bamboo tissue contains starch granules, influencing its susceptibility to fungi and beetles. Starch content varies based on season, age, culm part, and species, indicating its role as an energy resource for shoot production. The use of bamboo as a sustainable construction material does requires treating bamboo with proper products to avoid insect attacks and therefore future structural material issues.

Density of Bamboo (Moso vs Guadua)

Comparative characteristics values of density analysis reveals Guadua's higher density, likely attributed to its moisture content. Both bamboo species exhibit densities comparable to timber commonly used in exterior joinery.

Hardness of Bamboo (Moso vs Guadua)

Janka hardness tests indicate that Moso bamboo is one of the hardest species as its characteristic values for hardness is approximately twice that of Guadua. Moso's hardness, comparable to European Oak, makes it suitable for applications requiring resistance to indentations.

Mechanical Properties: Strength of Bamboo

The determination of the physical strength, with four-point bending tests reveal Guadua has a higher strength than other especies of bamboo and a large difference in its modulus of elasticity (MOE) and bending strength (MOR) compared to Moso. Guadua is deemed suitable for load-bearing applications (strength class C35), while Moso's low MOE suggests limitations in load-bearing capacities. Compressive strength tests done in Colombia by The Best Bamboo at la Universidad de Ingenieros also showed Guadua superior to Moso on vertical stress.

Gluability of Bamboo (Moso and Guadua)

In the realm of bamboo applications, understanding the gluability of different bamboo species is crucial for various industries, from construction to furniture manufacturing. In our pursuit of excellence, we have conducted extensive gluability tests with two prominent bamboo species, Moso and Guadua, using commonly employed adhesives such as EPI-glue and PVAC-glue.

Our comprehensive testing reveals promising results, showcasing that both Moso and Guadua can be effectively bonded using common glues, particularly EPI-glue and PVAC-glue. This broad compatibility opens up a range of possibilities for incorporating bamboo into diverse applications, reinforcing its standing as a versatile and sustainable material.

Moso's Superior Performance with PU-glue:

The exceptional performance of Moso bamboo in conjunction with PU-glue underscores its potential for applications demanding heightened bonding strength. This revelation is particularly significant for industries that prioritize not only the eco-friendly aspects of bamboo but also require exceptional adhesive performance, such as in structural components and engineered bamboo products.

Implications for Industries:

For manufacturers and designers seeking optimal performance in their bamboo-based projects, these findings offer valuable guidance. The selection of bamboo species and adhesive can be tailored to specific project requirements, ensuring the desired balance between sustainability and performance.

Santiago Perdomo - CEO of The Best Bamboo with Guadua Laminated Lumber

Treatability of Bamboo (Moso vs Guadua)

Pressure treatment with a copper solution indicates Guadua's higher treatability compared to Moso. Both bamboo species show treatability comparable to Norway spruce and Scots pine.

Final Conclusion

While laminated bamboo, in its natural state, may not be recommended for outdoor applications, bamboo composite (strand woven bamboo) holds promising potential. Both Guadua and Moso meet mechanical requirements and tested properties, aligning closely with commonly used timber species. The comprehensive test results provides valuable insights for understanding the mechanical characteristics of these different species of structural bamboo as the developing world requires the construction industry to adopt alternative non-conventional renewable materials to reduce the unsustainable level of greenhouse gas emissions.

This page is a summary of the full test report, which can be downloaded here: Bamboo for Exterior Joinery.The report is written by Valentijn de Vos